A+H ANLAGENTECHNIK

A+H ANLAGENTECHNIK

REFERENCES IN DETAIL

REFERENCES IN DETAIL

REFERENCES IN DETAIL

WATERWORKS IN COESFELD.

WATERWORKS IN COESFELD.

WATERWORKS

COESFELD.

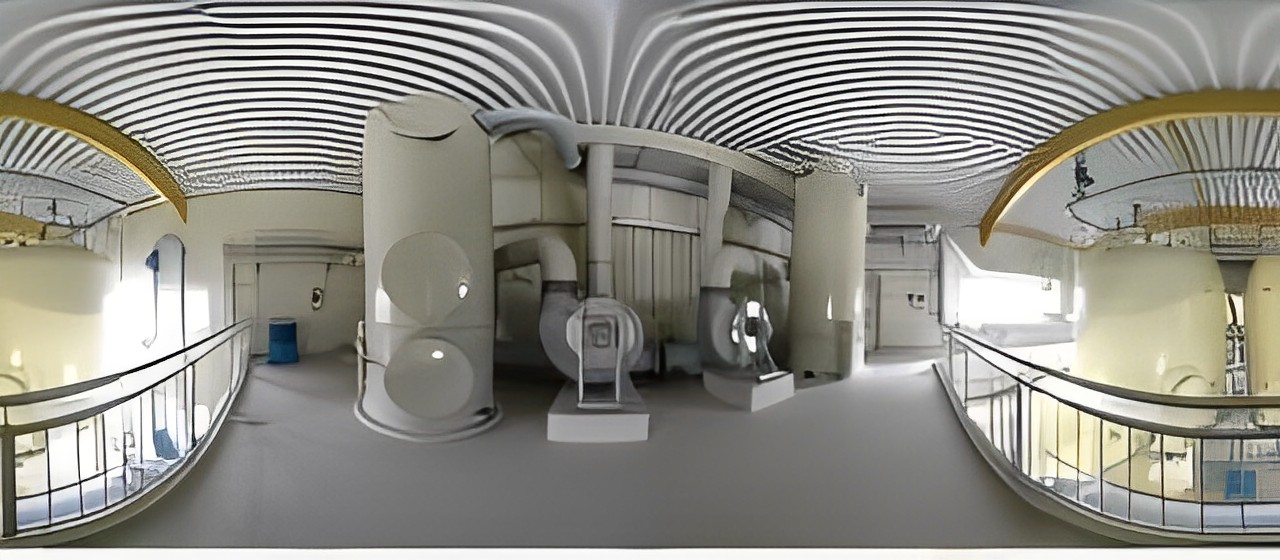

Waterworks in Coesfeld

Via the wells of the existing raw water extraction, the water is led through the newly installed physical deacidification plant (2 pieces of Riesler with 6,600m3/d each ) and reaches two intermediate storage tanks. From these, the water is pumped via a controlled intermediate pumping station to the 2 softening reactors, treatment capacity per reactor max. 6,600m2/d fed, with the aim of softening to 10°dH. This is followed by a 2-stream filtration stage consisting of 4 steel pressure filters for turbidity filtration, each with a capacity of 3,000m3/d. After that, the water enters two clean water chambers with a capacity of 350 m3 each. The network pumping station consists of 3 pieces of vertical, frequency-controlled high-pressure pumps with a capacity of 6,600m3/d each. They take over the distribution of water into the supply network. Numerous ancillary plants have been installed for the treatment of the raw water to drinking water in accordance with the TVO specifications, as well as for the post-treatment of the rinsing wastewater:

- Flushing water pumping station

- Complete lime milk preparation and dosing plant for the production of lime milk from white fine lime.

- Fully automatic supply of the softening process with quartz sand as seed grain

- Drainage, storage and disposal facilities for the residues from the softening process

- CO2 storage and metering system for volume-proportional metering of carbon dioxide into the reactor discharge line. (for the adjustment of the lime-carbonic acid balance).

- Neutralization plant for the neutralization of rinsing wastewater from softening

- Chlorine gas, control and dosing system

- Sludge pumping station and sludge treatment of the residues from filtration, including a flocculant dosing system.

- Compressed air supply systems for the control of fittings and aggregates in the treatment process

Click on one of the images below to open an interactive 360 panorama. You can click, hold and drag within the panorama to the desired viewing direction.