Waterworks in Löhnen

A+H ANLAGENTECHNIK

A+H ANLAGENTECHNIK

REFERENCES IN DETAIL

REFERENCES IN DETAIL

REFERENCES IN DETAIL

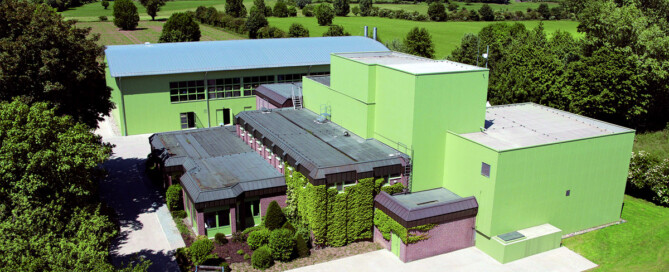

WATERWORKS IN LÖHNEN.

WATERWORKS IN LÖHNEN.

WATER WORK IN

RELEASE.

Löhnen waterworks, Dinslaken municipal utility: Drinking water treatment with state-of-the-art technology – Germany’s largest nanofiltration plant

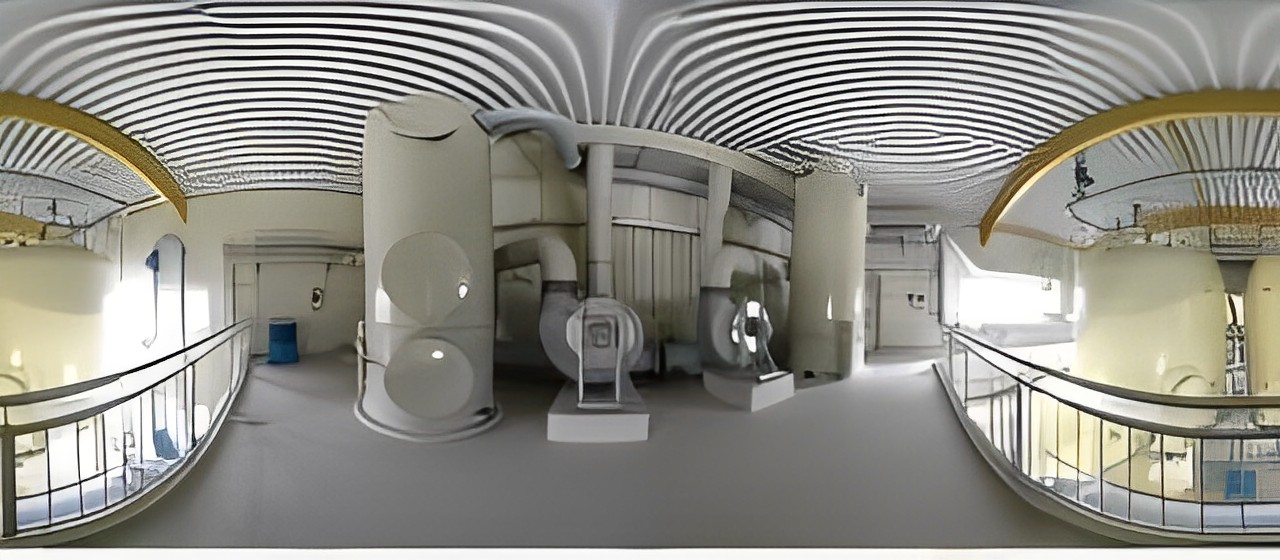

The construction of this facility was required to preemptively counteract changes in the flow conditions of the groundwater wells that are expected to occur due to the decline in coal mining development. Trace substances from the Rhine bank filtrate could enter the groundwater wells that may not be safely removed using conventional treatment technology. The newly installed treatment system ensures the removal of ions and particles in the nanometer range by means of pressure-driven membrane modules. Description of the plant: The raw water from the existing water extraction is stored in 2 raw water chambers of 600m each. From here, the raw water is fed to the suction side of the 11 FEED pumps, which in turn convey the raw water via 11 membrane module lines, with the addition of an antiscalant to prevent scaling on the membrane modules. The water passed through the nanofiltration lines is called PERMEAT. After the membrane passage it is buffered in 2 permeate tanks of 300m3 each. From here, a permeate pumping station transfers the water to the pump receiver of the conventional treatment plant. The operation of a nanofiltration plant is very complex and requires numerous auxiliary systems for its function. These include:

- Antiscalant, (copmplex binder) supply and dosing system

- Preservative, (e.g.NaHSO3) storage and dosing system

- Acid, (e.g.H2SO4)- storage and dosing system

- Lye, (e.g. NaOH)- storage and dosing system

- Flushing and cleaning pumping stations

- Neutralization tank with periphery

- Conveying, monitoring and discharge of the concentrate

Click on one of the images below to open an interactive 360 panorama. You can click, hold and drag within the panorama to the desired viewing direction.